Okay, so I got into watches a while back, you know, the mechanical kind. And like most people, I was totally hooked on how these tiny machines work. I spent a lot of time watching videos and reading stuff online, but I really wanted to see the guts of a watch for myself. So, I bought a cheap mechanical watch, and the first thing I did was tear it apart.

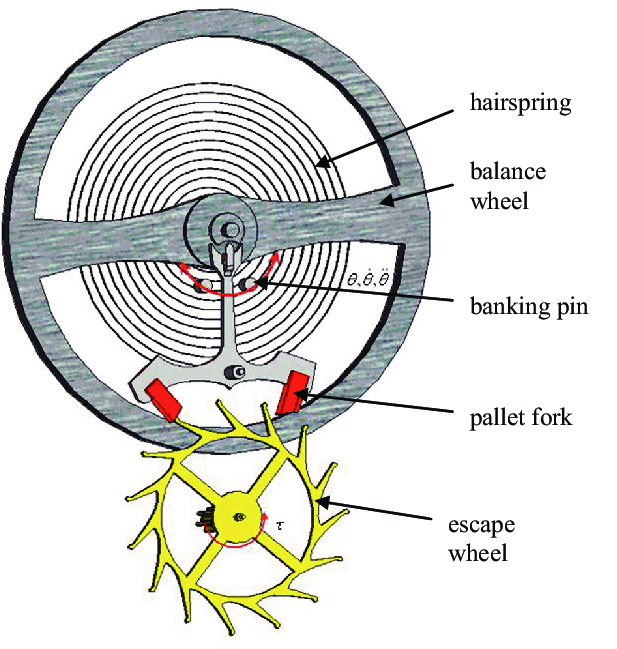

I was particularly interested in this thing called the escapement, specifically, the pallet fork. I mean, this little guy is the heart of the watch. It’s what makes it tick, literally! Anyway, after I removed the case back, I could see the balance wheel swinging back and forth like crazy.

Then, using a pair of tweezers, because all this stuff is super tiny, I started taking apart the movement. It was a bit nerve-wracking, but I took it slow. I removed the balance wheel first, carefully setting it aside. With that out of the way, I could finally get a better look at the pallet fork.

This little, Y-shaped piece was moving back and forth, locking and unlocking the escape wheel. It was amazing to see in action. I used a loupe to get a closer look, and I could see how the escape wheel’s teeth were pushing on the pallet fork’s arms, called pallets. That’s what was making it rock back and forth.

- First, I carefully removed the balance wheel assembly, making sure not to damage the delicate hairspring.

- Then, with the balance wheel out of the way, I unscrewed the pallet fork bridge, which is the tiny plate that holds the pallet fork in place.

- Next, I gently lifted out the pallet fork. It’s really small, so I had to be extra careful not to drop it or lose it.

I spent some time just examining the pallet fork under the loupe. I could see the two pallets, which are usually made of synthetic ruby, and the little fork part that interacts with the balance wheel’s impulse pin. It’s all so precisely made. To be honest, I was pretty amazed that someone figured out how to make something like this work in the first place.

After I was done admiring the pallet fork, I put the whole thing back together. I’m not gonna lie, it was a real pain. But I finally managed to do it, and guess what? The watch was still working! I felt like a real watchmaker for a minute there. It was a pretty cool experience, and it definitely gave me a much deeper appreciation for the complexity and ingenuity of mechanical watches. I learned a lot, and I felt pretty damn proud of myself for not completely destroying the watch.